to make a swap4l80e into the 96 caprice /my motor is ready and ill like to use a 4l80e tranny i hear they are strong trannys. what do i need to make this swap happen?

gallo-lo

76 posts

·

Joined 2005

First, what are your goals for the car performance wise? Unless you're running lots of power I think the 80 eats up too much power and weighs more than the 60.

Mike

Mike

gallo-lo

Discussion starter

300 posts

·

Joined 2008

i want a durable tranny ,not saying 4l60 wont hold the power, but i just blu one with stock lt1, i have mild lt1 w hot cam set up, 342 gears 2.5 exhaust , im looking for an converter but im going to decide of using an 4l80. there rated hp 1000hp with some work.First, what are your goals for the car performance wise? Unless you're running lots of power I think the 80 eats up too much power and weighs more than the 60.

Mike

486 posts

·

Joined 2008

For the 4L60E to 4L80E swap I've heard you need a transmission controller for it, and those can get a bit expensive. Also its a bigger and heavier transmission so would make our already heavy cars heavier, also the transmission tunnel will have to be modifed. Additionally it also takes more power to turn it so would have more of a power loss. The tail shaft would also have to be swapped out and those apparently are not cheap either. See http://forums.corvetteforum.com/c4-...orum.com/c4-tech-performance/1781147-4l60e-to-4l80e-conversion-adapter-kit.html for a little more information. - Peter

7,300 posts

·

Joined 2003

I posted my "link" - JaySS!

Yeah, go look at the logic diagrams. Everything is the same except for one on-off shift solenoid.

Yeah, go look at the logic diagrams. Everything is the same except for one on-off shift solenoid.

26 posts

·

Joined 2001

Here you goI posted my "link" - JaySS!

Since there have been several interested people on this I’ll go ahead and outline what we did to change over a ’95 Impala to a 4l80E.

While the reasons to stay with the 4L60E can be argued until everyone is blue in the face, the fact is that we felt the 4L80E was better a long-term solution for our application. It is important to clarify that it is _not_ necessary to use an aftermarket transmission controller, the LT1 PCM _can_ control the 4L80E. As far as the weight/rotating mass argument goes – well, first of all we weren’t that concerned as this isn’t a drag car, and secondly, the same was said when the Syclone and Typhoon guys started changing over from the 700R4’s to the 4L80E’s. But what was found was they generally ran the same or up to 2 tenths quicker, something they attribute to the quicker shift event times and/or reduced RPM drop on the 1-2 shift. This is only an explanation of what we did, not necessarily an argument for/against the changeover.

Mechanicals:

We purchased a used 4L80E locally from a 2500 Chevy Express van, something like a 2003 or so, just before they were switched to the LS engines. The converter is supposed to be the loosest one that the factory offered (look for 2000 - up small block applications) so it has a stall speed not too far from a factory SS converter. Dropping $800.00 - $1000.00 for a decent lockup converter wasn’t in the cards at this time, so we tried to get as close as we could and upgrade later, if necessary. To mount it into the Impala, we obtained a 4L80E crossmember from Dan @ CIA.

Since the 4L80’s use the large ring gear, and there isn’t room to readily adapt it to the smaller 153 tooth Impala flexplate, we bolted it up using a 168 tooth flexplate (from a 350 powered ¾ ton pickup) found on eBay. As the LT1 blocks are already double drilled for both starter configurations, we then selected a 454 gear reduction starter (as used on the ‘96 – up Vortec 454's) and that went in by just rerouting the starter cable. By going to the larger ring gear flexplate, we were able to reuse the converter that came with the transmission. Note that iIf you were to obtain an aftermarket converter this step would be unnecessary, as most are available in the smaller - 153 tooth - bolt pattern.

The trans went in as is, without having to slice the converter dust shield mounting ears as we had expected we might need to. As the car is equipped with FLP headers, they may have helped this time. In this instance, the starter to header clearance actually improved, but you may not be so lucky with your particular configuration. There was no floorpan massaging necessary to fit, though it is a bit tight in a couple areas. Since our 4L80E was a post-1997 model, it was necessary to lengthen the cooler return line to reach the rearmost fitting, easily handled with a section of brake tubing, a compression union, and some careful bending.

The shift cable was too short by about 5 inches – we ended up going to the wrecking yard and selecting several that looked like they might work. Not sure what we eventually ended up with, but a Blazer unit might be a good place to start. The floor shift conversion was performed while the car - again this was on a ’95 SS - was still running the 4L60E. At that time the column linkage was retained to actuate the reverse lights, etc. That had to go clearance reasons - it is necessary to tie into the combination switch on the 4L80 range selector shaft - similar to the setup used in the '96 Impalas – to get the safety interlocks and reverse lights back up and operational.

Everything we could find showed that the 4L80E is 5/8" longer than the 4L60E. Since the car had already been fitted with the extended rear control arms, we were thinking of reinstalling a factory shaft with a conversion U joint to fit the larger yoke, but as it turned out we couldn’t locate a nice unit quickly and ended up having the existing aftermarket shaft cut down 1 inch by a local shop. It was their opinion that the conversion joint was not the best solution in terms of future availability and recommended that we proceed welding in the proper end, so we followed their advice.

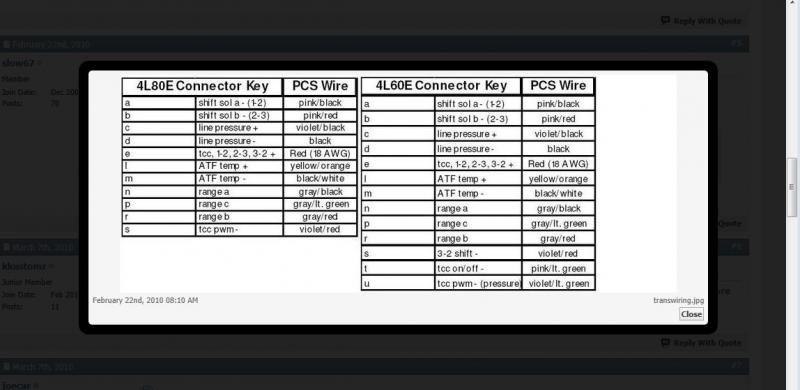

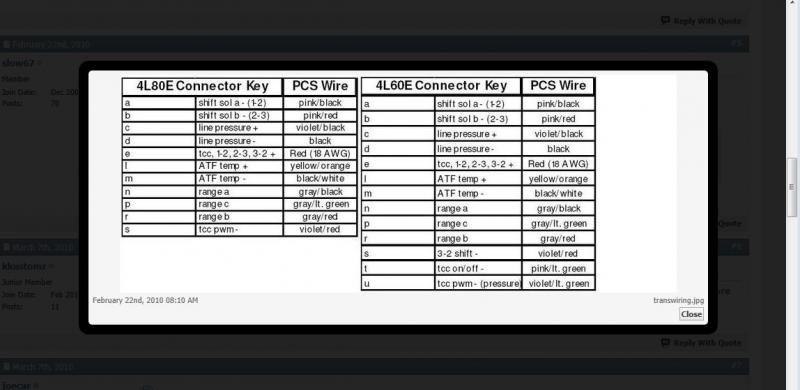

Electricals: You will want to tie into the combination switch as mentioned above. It may have been necessary to re-pin the VSS connector to fit the 4L80E housing. That would be a function of year, as the ’94 & ’95 cars use a different connector than the 96’s. Using the ’95 FSM and 4L80E SRTA manual, the car’s transmission connector was repopulated to match what the transmission expected. To accommodate the inverted logic of the ‘Shift B’ solenoid, the output line from the PCM was split and a tied into a standard Bosch relay at Pin 30, with the transmission side tied to the normally closed – 87A – contacts. The coil contacts - 85 & 86 - are supplied by an ignition-switched source. See http://www.teamrocs.com/technical/pages/relay_basics.htm if you need a better explanation.

That is pretty much it except for the PCM programming, there are a number of people that can better speak to the table values that should be modified to account for the various transmission differences better than I can, so I’ll defer to them for that.

Once out on the road, we did find that the shifting was softer that we had expected, that may be due to the OEM van application our transmission was sourced from, so a TransGo kit was installed and then the car brought back to do the final adjustments on the shift firmness.

This is pretty much what was needed to put a 4L80E where the 4L60E was. Hopefully this will give everyone an idea of what to expect if they are contemplating doing the same.

- J

1,166 posts

·

Joined 2008

holy crap. all the trouble u went thru to get the 4l80e transmission under there. i guess i'll just upgrade to a level 2 4l60e. im doing a motor swap for an lq4 engine and my eyes are bleeding from research and my brain are extremely tired. i learn so much with lq4 and many parts to throw at it and how to make it work for our cars. and how extremely headache it is to do the wire harness. i think that's enough for me for now i dont wanna get into the transmission since i do not own a hydraulic lifter to put my car in the air =/

2,336 posts

·

Joined 2003

You should also consider the gearing differences between the two, because the shorted OD of the 80e will limit your rear gear choice if you plan to do much highway driving. Rather, if you like to drive fast on the highway.

If I were to do it again, I'd consider a 2004R. But truth be told, you don't need more than the 4l60e for a mild heads cam car.

If I were to do it again, I'd consider a 2004R. But truth be told, you don't need more than the 4l60e for a mild heads cam car.

893 posts

·

Joined 2006

Rat you don't like your 80? Hell it seems the only way for me if I wanna drive on the street any

2,336 posts

·

Joined 2003

It's just not optimal from a highway cruise perspective, i.e. street driving. That's why I'd consider a 2004R, better gearing than both a 60 or 80e, and supposed to be strong as hell when built right.Rat you don't like your 80?

I'm not sure what you mean by this. Do you primarily street race? Otherwise, a 4L60E is perfectly suited to street driving.it seems the only way for me if I wanna drive on the street any

324 posts

·

Joined 2009

In one of the post it stated that a bbc starter was used due to the 168 flywheel which in turn was used because the converter didnt have dual bolt patterns, i.e 153 tooth and 168.

893 posts

·

Joined 2006

oh ok, so you can use normal starter if you use the LT1 flywheel, just got to make sure the converter matches tranny/engine and if you go that route space wont b an issue, gotcha, I'm GTG!

374 posts

·

Joined 2008

4l80e Questions

I have seen a couple threads asking and answering questions on the 4L80E but I am left with a couple questions myself.

I have a couple projects going on, both involving the 0411 PCM and am wondering,

What year model 4l80e's will work with the newer 0411 PCM?

Also, what year(s) can be tricked with a solenoid and used with the LT1 PCM?

If anyone esle has questions or facts about the 4l80e feel free to post it up here

Thanks alot guys,

ZACH

I have seen a couple threads asking and answering questions on the 4L80E but I am left with a couple questions myself.

I have a couple projects going on, both involving the 0411 PCM and am wondering,

What year model 4l80e's will work with the newer 0411 PCM?

Also, what year(s) can be tricked with a solenoid and used with the LT1 PCM?

If anyone esle has questions or facts about the 4l80e feel free to post it up here

Thanks alot guys,

ZACH

748 posts

·

Joined 2007

You'd want a 97-later 4L80E to use with the 0411 PCM. /i also think those years were "stronger" than the pre-97s. If you contact HPTuners support, then they should be able to do a segment swap for you. I'm not too sure as to the solenoid trick.

2,336 posts

·

Joined 2003

I've been told that you no longer need to use a solenoid with the LT1 PCM. Apparently the latest Tuner Cat allows you to reverse the Shift B solenoid in the PCM. Therefore, swapping to a 4L80E should involve nothing more than changing pin-outs and a few PCM tweaks.

I'm currently using a separate TCU for my 4L80E, but I'm going to try and make it work with the LT1 PCM this winter.

I'm currently using a separate TCU for my 4L80E, but I'm going to try and make it work with the LT1 PCM this winter.

2,336 posts

·

Joined 2003

Can someone please confirm this?

Also, Nab tells me that you have to move the tan TCC wire to the 3-2 downshift wire. Does that mean that you simply move the Tan wire to the 3-2 downshift pin hole? If so, is there no wire already there, and if something is there, then what are you supposed to do with it?

Finally, is this all that is needed? What other tuning changes should be or could be made to make the 4L80E work best?

Some reference links: http://www.msgpio.com/manuals/mshift/4L80E/4L80e.html#settings

Tunercat definition file $EE CY is required for this... http://www.tunercat.com/pdfs/pcm_$ee.pdfhttp://www.camaroz28.com/forums/com...ter-diagnostics-tuning-36/ecm-configuration-file-version-cv-723618/#post6183526

Yes, for the 4L80E the switches should be set as follows:

X Shift Solenoid A - 1st Gear (X=Enabled)

0 Shift Solenoid A - 2nd Gear (X=Enabled)

0 Shift Solenoid A - 3rd Gear (X=Enabled)

X Shift Solenoid A - 4th Gear (X=Enabled)

0 Shift Solenoid B - 1st Gear (X=Enabled)

0 Shift Solenoid B - 2nd Gear (X=Enabled)

X Shift Solenoid B - 3rd Gear (X=Enabled)

X Shift Solenoid B - 4th Gear (X=Enabled)

Also, Nab tells me that you have to move the tan TCC wire to the 3-2 downshift wire. Does that mean that you simply move the Tan wire to the 3-2 downshift pin hole? If so, is there no wire already there, and if something is there, then what are you supposed to do with it?

Finally, is this all that is needed? What other tuning changes should be or could be made to make the 4L80E work best?

Some reference links: http://www.msgpio.com/manuals/mshift/4L80E/4L80e.html#settings

2,336 posts

·

Joined 2003

There are only 2 changes required for an LT1 PCM to support a 4L80E!

I've collected the below from above in hopes that I can do a better job of explaining here. I'm going off of memory and what I wrote above, so it's possible that I could miss something or remember wrong, but here goes.

________________________________________________________________

1) Change "Shift Solenoid B": Reverse it for the 4L80E !

Congrats, you're half way there.

________________________________________________________________

2) TCC Lockup using "TCC Enable": MOVE Tan/Blk wire from pin T to pin S at Trans connector

________________________________________________________________

Congrats, you're now done with the wiring and the PCM will control a 4L80E!

________________________________________________________________

Throw in some shift point and TCC lockup adjustments to finish off the project.

Note: Plan to adjust the wiring harness (move the exits from the main harness) to accomodate the longer 4L80E, which also places connectors on opposite sides of the car.

I've collected the below from above in hopes that I can do a better job of explaining here. I'm going off of memory and what I wrote above, so it's possible that I could miss something or remember wrong, but here goes.

________________________________________________________________

1) Change "Shift Solenoid B": Reverse it for the 4L80E !

Can be accomplished using either a relay (not explained here, look it up) or by re-programming the PCM, literally 2 changes in the SWITCH (1st) table.

Note: Requires a specific TunerCat definition file version CY.

Congrats, you're half way there.

Still confused

- Get CATS Tuner (aka Tunercat), version 2.26 will work.

- Get ECM file PCM_EE, MUST be version CY!

- Read your current PCM and save the file

- Open the ECM SWICH TABLE

- Change the selections for Shift Solenoid B according to the chart below.

- Write the new file to the PCM.*

* Note: Look before you write. Does the Injector size in the constants table look right?

X Shift Solenoid A - 1st Gear (X=Enabled)

0 Shift Solenoid A - 2nd Gear (X=Enabled)

0 Shift Solenoid A - 3rd Gear (X=Enabled)

X Shift Solenoid A - 4th Gear (X=Enabled)

0 Shift Solenoid B - 1st Gear (X=Enabled)

0 Shift Solenoid B - 2nd Gear (X=Enabled)

X Shift Solenoid B - 3rd Gear (X=Enabled)

X Shift Solenoid B - 4th Gear (X=Enabled)

0 Shift Solenoid A - 2nd Gear (X=Enabled)

0 Shift Solenoid A - 3rd Gear (X=Enabled)

X Shift Solenoid A - 4th Gear (X=Enabled)

0 Shift Solenoid B - 1st Gear (X=Enabled)

0 Shift Solenoid B - 2nd Gear (X=Enabled)

X Shift Solenoid B - 3rd Gear (X=Enabled)

X Shift Solenoid B - 4th Gear (X=Enabled)

________________________________________________________________

2) TCC Lockup using "TCC Enable": MOVE Tan/Blk wire from pin T to pin S at Trans connector

But wait, it can be more complicated if you want, and there is information out there about using PWM for TCC that can trip you up if you read it and think there's got to be more to it than just this one wire change. See red highlighted section at the bottom for a link to a write up.

Congrats, you're now done with the wiring and the PCM will control a 4L80E!

________________________________________________________________

Want to improve the tune for better shifts and TCC lockup? Here are the tables that you'll want to adjust:

Main Line Pressure Tables: Put these back to near stock!

Shift Points: Based on personal preference and rear gear, you may like it to shift earlier or later.

Shift Time: I cut them down to reduce shift time, and it feels better to me.

TCC Lockup: Based on personal preference and rear gear, you will need to raise these in 3rd and 4th gear. Play with the speeds to adjust to your preference.

see attached SAMPLE: http://www.impalassforum.com/vBulletin/attachment.php?attachmentid=88337&stc=1&d=1405452240

Main Line Pressure Tables: Put these back to near stock!

Note: DO NOT RUN HIGH LINE PRESSURE (over 100) ON A 4L80E, else it will burn up quickly!!!

Shift Points: Based on personal preference and rear gear, you may like it to shift earlier or later.

- Normal Up/Down Shift Points

- Performance Up/Down Shift Points

- Kickdown Up/Down Shift Points

- Kickdown Mode Up/Down Shift Points

Shift Time: I cut them down to reduce shift time, and it feels better to me.

- Shift Time (sec) Vs. %TPS Vs. Shift, Normal Mode, Low Alt.

- Shift Time (sec) Vs. %TPS Vs. Shift, Normal Mode, High Alt.

TCC Lockup: Based on personal preference and rear gear, you will need to raise these in 3rd and 4th gear. Play with the speeds to adjust to your preference.

- TCC Normal Mode Engage MPH Vs. Gear Vs. %TPS

- TCC Normal Mode Release MPH Vs. Gear Vs. %TPS

- TCC Cruise Mode Engage MPH Vs. Gear Vs. %TPS

- TCC Cruise Mode Release MPH Vs. Gear Vs. %TPS

Can someone please confirm this?

Tunercat definition file $EE CY is required for this... http://www.tunercat.com/pdfs/pcm_$ee.pdf

Also, Nab tells me that you have to move the tan TCC wire to the 3-2 downshift wire. Does that mean that you simply move the Tan wire to the 3-2 downshift pin hole? If so, is there no wire already there, and if something is there, then what are you supposed to do with it?

Finally, is this all that is needed? What other tuning changes should be or could be made to make the 4L80E work best?

Some reference links: http://www.msgpio.com/manuals/mshift/4L80E/4L80e.html#settings

It's an OBD-1 conversion. I hope that it works just as well with an OBD-2 PCM, because I'm planning to buy the DST kit from Jet. I just wanted to make sure this would work using the tuning software I already had on hand before plopping down another $400.

I looked at the TCC tables, and I don't see why it was locking so low like it did. I also need to find out which tables control the TCC in a 4L80E. I think I read that the 4L60E has two TCC signals (on off and PWM), whereas the 80E only uses PWM. The good news (temporarily) is that I don't need the TCC to race the thing! But I do need it for the street, and it's still a street car.

I'm almost finished with the job. The only thing left is to sort out the TCC lockup. Everything else seems to be working perfectly. Other than the changes to the switch table for the 4L80E solenoid pattern, I've pretty much kept all of the trans tables the same as the 4L60E. I only changed the shift RPM's and cut the normal mode shift times in half. It shifts perfectly and I like the faster shifts. I think that it drives better with the LT1 computer than it did with the PCS TCU.

So about the TCC. I had originally moved the Brown wire from U to S. On the first test drive it was locking the converter way too soon, as if it was set to lock at too low a speed. So I decided I must have swapped the wrong wire. So I then moved the Tan Black wire that was in T to S, which is the one Nab had told me to use in the beginning. However, now I don't get TCC at all. I guess I was right in thinking Nab was wrong. Anyway, I'll take a closer look at the bin file to see if the TCC tables are goofed up. If so, then I guess I put the brown wire from pin U back into pin S and adjusting the TCC tables.

So far I'm please with how well the LT1 PCM controls the 4L80E, and I'm happy that it didn't require the use of a relay to make it happen. TunerCat to the rescue!

Good news, the TCC lockup is working, and Nab was correct about moving the PCM_C4-11 (Transmission TCC Solenoid) Tan/Blk wire to position S in the trans connector. The reason I didn't have TCC lockup the first time I test drove it was because I didn't let it get up to operating temp. It was below freezing that night and I was being too cautious about running an untested setup to far from home late at night. Tonight I took for a much longer drive, and it definitely locked up this time. I felt it lock, and I have a DM log that shows it.

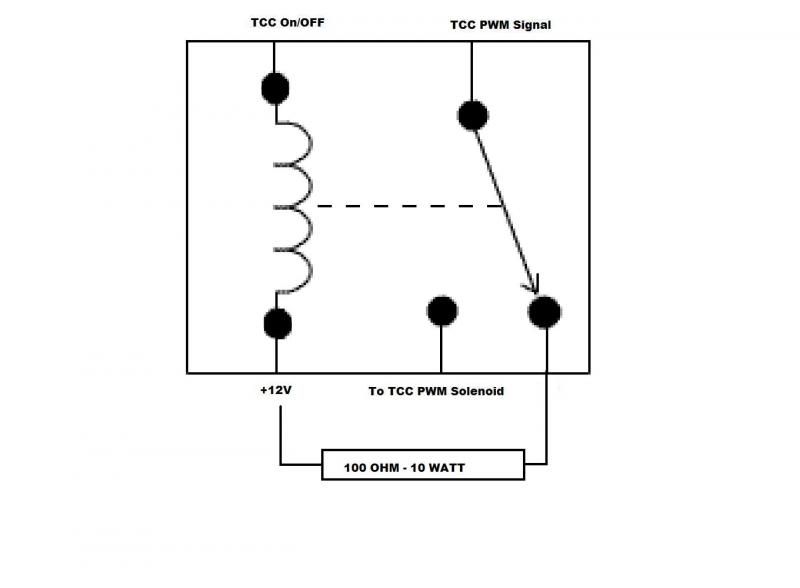

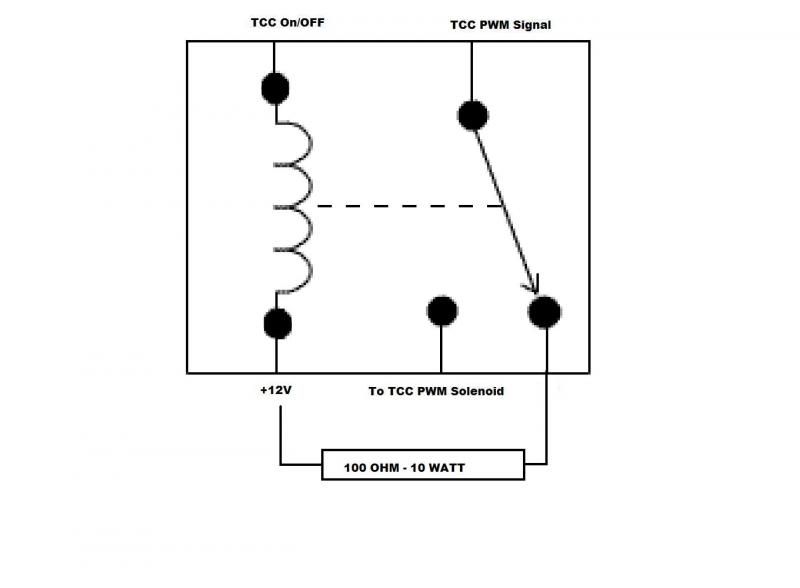

Also, using the TCC Enable signal is just one of the ways to do this. Thanks to the efforts of brilliant minds over at EFI Live, there is another option involving a relay that lets you use the TCC PWM signal to pulse the TCC PWM Solenoid, Link ---> link. It requires that you use the TCC Enable signal to latch a relay that drives the PWM signal on the S position at the Trans connector.

Attachments

-

17.3 KB Views: 646

2,336 posts

·

Joined 2003

I'm almost finished with the job. The only thing left is to sort out the TCC lockup. Everything else seems to be working perfectly. Other than the changes to the switch table for the 4L80E solenoid pattern, I've pretty much kept all of the trans tables the same as the 4L60E. I only changed the shift RPM's and cut the normal mode shift times in half. It shifts perfectly and I like the faster shifts. I think that it drives better with the LT1 computer than it did with the PCS TCU.

So about the TCC. I had originally moved the Brown wire from U to S. On the first test drive it was locking the converter way too soon, as if it was set to lock at too low a speed. So I decided I must have swapped the wrong wire. So I then moved the Tan Black wire that was in T to S, which is the one Nab had told me to use in the beginning. However, now I don't get TCC at all. I guess I was right in thinking Nab was wrong. Anyway, I'll take a closer look at the bin file to see if the TCC tables are goofed up. If so, then I guess I put the brown wire from pin U back into pin S and adjusting the TCC tables.

So far I'm please with how well the LT1 PCM controls the 4L80E, and I'm happy that it didn't require the use of a relay to make it happen. TunerCat to the rescue!

So about the TCC. I had originally moved the Brown wire from U to S. On the first test drive it was locking the converter way too soon, as if it was set to lock at too low a speed. So I decided I must have swapped the wrong wire. So I then moved the Tan Black wire that was in T to S, which is the one Nab had told me to use in the beginning. However, now I don't get TCC at all. I guess I was right in thinking Nab was wrong. Anyway, I'll take a closer look at the bin file to see if the TCC tables are goofed up. If so, then I guess I put the brown wire from pin U back into pin S and adjusting the TCC tables.

So far I'm please with how well the LT1 PCM controls the 4L80E, and I'm happy that it didn't require the use of a relay to make it happen. TunerCat to the rescue!

1,359 posts

·

Joined 2002

Is that an OBD2 PCM or an OBD1 conversion PCM in your car? Do you think that OBD1 vs. OBD2 would make a difference?So far I'm please with how well the LT1 PCM controls the 4L80E, and I'm happy that it didn't require the use of a relay to make it happen. TunerCat to the rescue!

2,336 posts

·

Joined 2003

Good news, the TCC lockup is working, and Nab was correct about moving the PCM_C4-11 (Transmission TCC Solenoid) Tan/Blk wire to position S in the trans connector. The reason I didn't have TCC lockup the first time I test drove it was because I didn't let it get up to operating temp. It was below freezing that night and I was being too cautious about running an untested setup to far from home late at night. Tonight I took for a much longer drive, and it definitely locked up this time. I felt it lock, and I have a DM log that shows it.

Also, using the TCC Enable signal is just one of the ways to do this. Thanks to the efforts of brilliant minds over at EFI Live, there is another option involving a relay that lets you use the TCC PWM signal to pulse the TCC PWM Solenoid, link. It requires that you use the TCC Enable signal to latch a relay that drives the PWM signal on the S position at the Trans connector.

Also, using the TCC Enable signal is just one of the ways to do this. Thanks to the efforts of brilliant minds over at EFI Live, there is another option involving a relay that lets you use the TCC PWM signal to pulse the TCC PWM Solenoid, link. It requires that you use the TCC Enable signal to latch a relay that drives the PWM signal on the S position at the Trans connector.

1,732 posts

·

Joined 2012

So why is the 80e not a good match for highway driving? I'd think that the higher amount of gears would drop highway rpm's nicely, especially for cars with rear end gear swaps. It'd be nice to not be spinning 3000rpm cruising down the highway.

3,860 posts

·

Joined 2005

4l80 vs. 4l60 vs. 200r4so why is the 80e not a good match for highway driving? I'd think that the higher amount of gears would drop highway rpm's nicely, especially for cars with rear end gear swaps. It'd be nice to not be spinning 3000rpm cruising down the highway.

2.48 vs. 3.06 vs. 2.74

1.48 vs. 1.63 vs. 1.57

1.00 vs. 1.00 vs. 1.00

0.75 vs. 0.69 vs. 0.67

3.73 * 0.75 = 2.80

3.73 * 0.69 = 2.57

3.73 * 0.67 = 2.50

Best for highway driving, actually, is the 200r4's 4th gear.

Too bad we didn't wind up with a 200r4E, gear spread looks better for our purposes.

3,262 posts

·

Joined 2007

The 4l80 has the same amount of ranges as the 4l60. It just has slightly lower ratios. Ratssled has a 3.42 gear in the car IIRC, because it delivers the same overdrive ratio as a 3.73 and the OD in the 4l60. All overdrives lower final drive in gear rpm for sure. The 4l80e doesn't drop rpm as far as the 4l60E.

Chris

Chris

2,517 posts

·

Joined 2000

Just a update: April's car is still running great with the 4L80 controlled by OBD1 LT1 pcm as Glen described above.

She drag raced it at Island dragway a couple weeks ago and even though we trailered it, she had to drive it home because our truck started running shizzy-like.

Her car has a 377 and 4.56 gears and was running 13.0s consistently.

Nab

She drag raced it at Island dragway a couple weeks ago and even though we trailered it, she had to drive it home because our truck started running shizzy-like.

Her car has a 377 and 4.56 gears and was running 13.0s consistently.

Nab

2,336 posts

·

Joined 2003

What to do with second VSS?

If you're wondering where to connect the VSS connector on the LT1 harness, it gets plugged into the VSS at the rear of the 4L80E, similar to a 4L60E. There is another identical speed sensor at the front, and people have asked what to do with this "second" VSS. You do nothing with it, because it's actually an ISS (Input Speed Sensor) that measures turbine speed, and it's not used in the LT1 PCM because 4L60E's don't have an ISS. It instead relies on engine RPM for detecting trans slip.

http://ls1tech.com/forums/13351794-post40.html

If you're wondering where to connect the VSS connector on the LT1 harness, it gets plugged into the VSS at the rear of the 4L80E, similar to a 4L60E. There is another identical speed sensor at the front, and people have asked what to do with this "second" VSS. You do nothing with it, because it's actually an ISS (Input Speed Sensor) that measures turbine speed, and it's not used in the LT1 PCM because 4L60E's don't have an ISS. It instead relies on engine RPM for detecting trans slip.

http://ls1tech.com/forums/13351794-post40.html

158 posts

·

Joined 2008

Thanks for all the help, I just made a deal on a 4L80E that was too good to pass up so I will be doing the 4L60e to 4L80e swap.

Just to make sure I have this covered, I have to

-flip the logic for the shift B solenoid with tunercats

-move the U brown wire into the S position

Is that all that is needed to make this work?

I understand I will need the 168 tooth flexplate and new starter to match.

Just to make sure I have this covered, I have to

-flip the logic for the shift B solenoid with tunercats

-move the U brown wire into the S position

Is that all that is needed to make this work?

I understand I will need the 168 tooth flexplate and new starter to match.

2,336 posts

·

Joined 2003

I don't think you want to follow the instructions in that image.

I think I only had to move that one wire to position "S".... and Nab was correct about moving the PCM_C4-11 (Transmission TCC Solenoid) Tan/Blk wire to position S in the trans connector.

158 posts

·

Joined 2008

**EDIT** From what I have read the "U" 4L60E PWM signal cannot be used to activate the "s" 4L80E TCC lockup because the 4L60 uses two signals to control lockup.. Not sure why the wire colors do not line up, maybe they are for newer LS style 4L60e and 4L80e.

Information I found says that either the "T" TCC on/off wire could be used but makes the TCC lockup harsh, other option is to use both 4L60E signals to control the TCC lockup with a relay. I dont know the guys who came up with this stuff but many thanks to them for sharing.

RatSSled, did you use the single wire "TCC ON/OFF" to control your lockup?

Information I found says that either the "T" TCC on/off wire could be used but makes the TCC lockup harsh, other option is to use both 4L60E signals to control the TCC lockup with a relay. I dont know the guys who came up with this stuff but many thanks to them for sharing.

RatSSled, did you use the single wire "TCC ON/OFF" to control your lockup?

158 posts

·

Joined 2008

RatSSled, did you use the single wire "TCC ON/OFF" to control your lockup?

also did you do any tuning due to the first gear difference or anything else trans related to the swap?

also did you do any tuning due to the first gear difference or anything else trans related to the swap?

2,336 posts

·

Joined 2003

I don't remember, but I thought I mentioned above that it's what I did. I really don't have the time to go pull the connector off and check. You could ask Blue Wail. He's also running a 4L80E with the stock PCM.

You adjust the shift and TCC lockup speeds to suit your preference. Once you get it on the road you'll know fairly quickly what you want to change. I had a standalone TCU before I got the PCM to work, so I already had a good template for those settings from years of previous tuning. I can send you my tune if want to look.

You adjust the shift and TCC lockup speeds to suit your preference. Once you get it on the road you'll know fairly quickly what you want to change. I had a standalone TCU before I got the PCM to work, so I already had a good template for those settings from years of previous tuning. I can send you my tune if want to look.

158 posts

·

Joined 2008

that would be great if you could send it, then I can compare tables. I am still trying to find the solenoid table in tunercats to reverse the logic for the shift B solenoid, I think my version is down level and I have to get the latest version.

158 posts

·

Joined 2008

Thanks, I found that my $EE file is downlevel, that is why I could not find the shift tables. Working on getting that updated now.

How harsh is your lockup using the ON/OFF rather than PWM control?

How harsh is your lockup using the ON/OFF rather than PWM control?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

- posts

- 1.9M

- members

- 48K

- Since

- 2000

A forum community dedicated to Chevy Impala SS owners and enthusiasts. Come join the discussion about performance, modifications, troubleshooting, maintenance, and more!

Explore Our Forums